Rice production in Pakistan holds an extremely important position in agriculture and the national economy. Pakistan is the world's fourth largest producer of rice, after China, India and Indonesia. Among the most famous varieties grown in Pakistan, include the Basmati, known for its flavor and quality.

In Pakistan Rice is the second staple food after wheat and is the second largest foreign exchange earner after cotton.

Major varieties grown in Sindh are Irri-9, Irri-6, D-98 while minor verities include Super Basmati. Major Rice growing areas in Sindh are Larkana, Dadu, Shikarpur, Qambar-Shahdadkot, Jacobabad, and kashmore districts in upper Sindh while Thatta, Badin, and Tando Muhammad Khan are major areas in lower Sindh.

In Sindh, rice is grown on about 2 million acres of land with per acre yield at 45 – 50 maunds, which like all crops in Pakistan does not reflect actual potential. Rice sector employs about half a million rural labor force. Overall, Sindh produces 35% of the country’s rice with annual production at around 3.5 million tons of which 2 million tons of milled rice is produced by more than 800 rice mills.

Our Rice Mill is:

-

Omni Private /Shikarpur Rice Mills

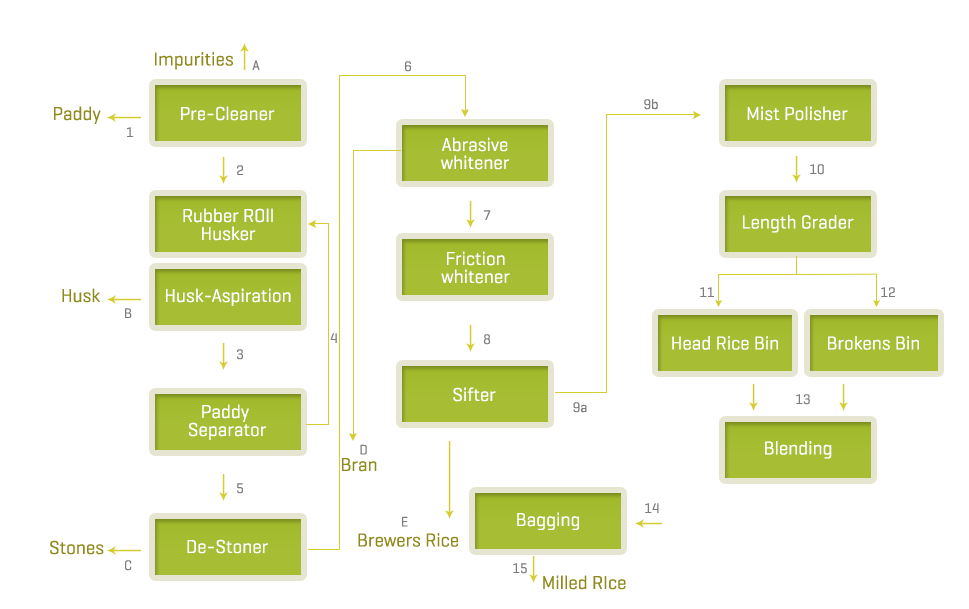

Rice Production Process

Key:

1. Paddy is dumped in the intake pit feeding the pre-cleaner

2. Pre-cleaned paddy moves to the rubber roll husker:

3. Mixture of brown rice and unhusked paddy moves to the separator

4. Unhusked paddy is separated and returned to the rubber roll husker

5. Brown rice moves to the destoner

6. De-stoned, brown rice moves to the 1st stage (abrasive) whitener

7. Partially milled rice moves to the 2nd stage (friction) whitener

8. Milled rice moves to the sifter

9. (For simple rice mill) ungraded, milled rice moves to bagging station

10. (For more sophisticated mill) milled rice moves to the polisher

11. Polished rice, will move to length grader

12. Head rice moves to head rice bin

13. Brokens moves to brokens bin

14. Pre-selected amount of head rice and brokens move to blending station

15. Custom-made blend of head rice and brokens moves to bagging station

A. Straw, chaff and empty grains are removed

B. Husk removed by the aspirator

C. Small stones, mud balls etc. removed by de-stoner

D. Coarse (from 1st whitener) and fine (from 2nd whitener) bran removed from the rice grain during the whitening process

E. Small brokens/brewer’s rice removed by the sifter

For more details, download our Rice Padding Receiving System document.